When Good Enough Can Be Great: Current-Only vs. Full Power Monitoring

You've decided to monitor energy use in your facility. The good news is that you've got a number of options to do this. The not-so-good news is that...

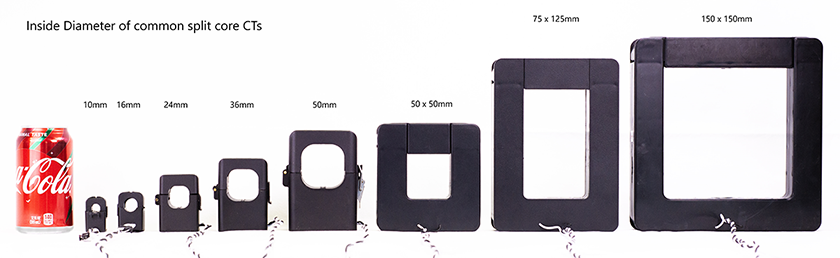

Current transducers (CTs) are a critical component of power monitoring. They come in a variety of formats, sizes, current ratings and accuracy levels. The aspect we would like to focus on here is size, specifically inside diameter.

The inside diameter (ID) is the width of the opening in the CT that the conductor goes through. It must be large enough to fit around the conductor, however choosing too large of a CT can create other issues. As the graphic above indicates, the overall dimensions of the CT grow substantially as the ID gets bigger.

Current rating

Be sure to use a CT with a current rating as close to the actual current being monitored as possible to maximize accuracy at the lowest possible load. A CT will be accurate across some portion of its range. For example, a 200 amp CT that is +/- 1% accurate might maintain that accuracy from 5% to 120% of its rated capacity (i.e. on loads between 10 and 240 amps).

Inside diameter

CTs of the same amperage come in different sizes. For example, Packet Power offers 200 amp CTs with 24mm, 36mm and 50mm IDs. The chart below shows that a 200A CT with a 50mm ID is much larger than one with a 24mm ID. Since space inside electrical equipment is often tight, using a CT that is larger than needed can create problems as well.

Split core CTs by inside diameter

CT sizing summary

Most customers will try to match the amperage of the CT to the rating of the over-current protection on the circuit. You need to know both the circumference of the conductor(s) that the CT has to fit around (to determine the minimum acceptable ID) and the amount of available space in the panel where the CTs will be installed. If the conductor is very large or the space is particularly tight, a Rogowski coil ("rope CT") might be the best choice.

Packet Power offers multi-circuit monitoring and branch circuit monitoring solutions that are custom-built to customer specifications. We've developed a configuration checklist to help customers create the ideal solution for their needs including the best split core CT.

Contact your Packet Power partner for more information. If there isn't a partner near you, contact sales@packetpower.com.

For a good overview of split core vs. solid core CTs reference "Split core, solid core, and why you should care".

You've decided to monitor energy use in your facility. The good news is that you've got a number of options to do this. The not-so-good news is that...

Conventional split-core CTs may not always be the best solution when installing current transducers on existing cable bundles. The CT may not fit...

The new monitors offer an easy way to add monitoring to some or all of the circuits on switchgear, panelboards, HVAC units, generators and other...