Split-Core CTs and Why Size Matters

Current transducers (CTs) are a critical component of power monitoring. They come in a variety of formats, sizes, current ratings and accuracy...

Conventional split-core CTs may not always be the best solution when installing current transducers on existing cable bundles. The CT may not fit around the conductor or in the required space. An easy alternative is to use a Rogowski coil.

Rogowski coils are flexible, thin rope-like loops that can be uncoupled to fasten around a conductor. Unlike conventional CTs, Rogowski coils do not have a ferrite / iron core but rather a continuous single spiral winding which allows them to be formed into an elliptical shape to match the conductor profile.

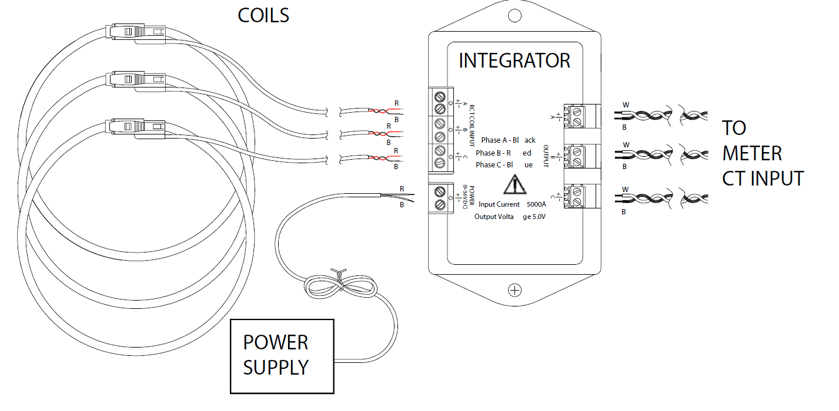

The coils produce an output that is typically fed into an integrator which in turn converts the signal into a standard CT signal for input into a power meter. Some power meters may accommodate Rogowski coil input without an integrator.

Unique features

Rogowski coil output is fixed regardless of the length of the coil. In other words, a 12-inch perimeter coil will have the same output as a 36-inch perimeter coil. The benefit is that the same coil can be used for a 2000A circuit or a 200A circuit as long as the integrator or meter is scaled accordingly.

Installation requirements

Most meters do not accept a native Rogowski coil's input and need an integrator to convert the signal from the native mV output to a standard CT output . The integrator is a small device that requires a power supply (typically 12-36V DC) and very low power (<1W).

Accuracy

Because of their relatively low output to current ratios, Rogowski coils may not be as sensitive to lower loads (<20A) as a typical iron core CT. The coil output on a 20A load may only be 1mV making it susceptible to noise. Accuracy can also be slightly affected by mounting geometry. Best practice is to have the coil centered and equidistant from the conductor.

Quality

Not all Rogowski coils are made with the same attention to quality. The manufacturing process is intricate and should include comprehensive testing.

Cost

Rogowski coils can be surprisingly economical compared to larger split-core CTs but are significantly more expensive in 4-inch (100mm) diameter size and below. It may be tempting to use a low cost coil but this usually comes at the expense of accuracy and quality.

Packet Power offers a comprehensive selection of CTs -- split-core, solid-core and Rogowski coils. Read the article explaining the difference between split-core and solid-core CTs.

Still have questions? Please contact your Packet Power Partner or email info@packetpower.com.

Current transducers (CTs) are a critical component of power monitoring. They come in a variety of formats, sizes, current ratings and accuracy...

Current Transducers are a key component of every power monitoring system. If you have ever wondered why they are used or how they work, here's a...

Power distribution units (PDUs), commonly referred to as power strips or rack mounted power distribution units (RMPDUs), are critical components...