Overview

Data centers require immense amounts of electricity to power, cool and operate the facility. Power represents up to 70% of a data center’s total operating costs. An accurate understanding of power utilization and environmental conditions is essential to improving energy efficiency, lowering costs, and ensuring high availability.

98% of data center managers say that a single hour of downtime costs over $100,000 with the largest facilities reporting the cost of a single hour of downtime at $1-5 million. Knowing your energy usage and environmental conditions allows you to maximize your operations for profitability while minimizing risks related to outages and equipment failure.

Data centers are complex facilities, and the jargon around data center power can sound like a foreign language. Here are data center acronym definitions that you may find helpful.

Getting started

Implementing power and environmental monitoring can feel overwhelming, but it doesn’t have to be. It should be a simple and low risk initiative that quickly provides tangible benefits through the data it delivers.

Implementing power and environmental monitoring can feel overwhelming, but it doesn’t have to be. It should be a simple and low risk initiative that quickly provides tangible benefits through the data it delivers.

Here are eight simple guidelines to getting started.

- Choose a solution that scales with your needs. Make sure you can add monitoring in steps and change your plans based on what you’ve learned. Avoid having to commit to an all-or nothing proposition.

- 80% of the value will come from paying attention to 20% of your systems. Focus on the biggest areas of need first to get the most value.

- Most things can be improved by 10% just by paying attention. Make sure the information you gather is easy to pay attention to.

- Avoid analysis paralysis. If you knew everything you needed to monitor, you probably wouldn’t need monitoring at all. Just do it. Deploying monitoring and adapting based on what you learn generally costs less than the RFP in search of the “ultimate” solution.

- Monitor what matters when it matters. Things change. Make sure your solution lets you easily focus on what you need to know, when you need to know.

- Gadgets do not save money, information does. A monitoring system is not about hardware or software. It is there to give you valuable information. Everything else is just a distraction and you should avoid it. Your system should make it easy to get the relevant information quickly and to share it.

- A monitoring system needs to show you the “so what”—where the savings are.

- Keep it simple. Adding real-time monitoring does not require replacing your unmetered equipment with new, but expensive equipment that has built-in metering. You can make any device a smart device with the right monitor.

Read the full article: How to grow into data center monitoring without breaking your budget or your career

Monitoring across multiple time scales

Data center infrastructure monitoring is not a one-size-fits-all proposition. There are many parameters you could monitor: power, energy, temperature, humidity, pressure, etc. There are also multiple levels in the power hierarchy that monitoring could be deployed at: main feeds, PDUs, cabinets, busways, servers, etc.

Data center infrastructure monitoring is not a one-size-fits-all proposition. There are many parameters you could monitor: power, energy, temperature, humidity, pressure, etc. There are also multiple levels in the power hierarchy that monitoring could be deployed at: main feeds, PDUs, cabinets, busways, servers, etc.

Obviously, you want a system that supports as many parameters as possible and covers them throughout the hierarchy. What is sometimes forgotten, however, is the dimension of time. Good monitoring also takes place on multiple time scales.

Real-time monitoring

Some monitoring is about catching things as they happen. This includes things like sudden load changes which may indicate failure or possibly unauthorized changes, rapid temperature fluctuations and water leaks. When these events occur, you want to know ASAP.

A monitoring system that supports real-time monitoring should make it easy to define alert conditions and provide multiple notification channels. It should also make it easy to define visual dashboards suitable for use in a NOC. It should support virtual, location-relevant dashboards that can quickly provide site-specific information. And it should make it easy for systems such as cooling optimization programs to access data on the fly.

Short-term monitoring

Short-term monitoring usually focuses on shorter (hours to weeks) time frame tasks or failure resolutions. It includes monitoring system migrations, cooling system rearrangement or tuning, data center expansion or consolidation and disaster recovery.

A system well suited for short-term monitoring applications should make it easy to define new, ad hoc reports and dashboards. It should also allow new sensors to be easily added or existing sensors to be moved if necessary.

Long-term monitoring

Long-term monitoring focuses on optimization over time (days to months), preventative maintenance and cost allocation. Long-term analysis is helpful to identify broad trends in usage and determine the underlying causes.

A good long-term monitoring system should allow you to analyze data at the appropriate time scale. With the right system you should be able to look at your reports and easily recognize patterns. Some of our customers can tell us what day of the week it was or the weather on any given day by just looking at the energy charts.

Allocating costs

Correctly allocation costs introduces some special requirements that warrant explicit mention. Reports must be able to match the billing calendar. Different organizations use widely different metrics to allocate costs (e.g. the highest peak power used or the actual energy consumed). The associated rules may be applied at the cabinet or cage levels or simply in aggregate for all use tied to one end customer. It may also require a variable rate schedule (e.g. peak vs off-peak power rates or usage in excess of an assigned limit). Finally, it needs to act as a system of record over time.

Common monitoring goals

Monitoring scope can run from watching every device to no monitoring whatsoever. What’s right for you depends on your business needs—and may involve fewer monitoring points than you might think. Here are monitoring options for some common goal scenarios.

Measure and track PUE

Good news - this just takes two data points: total facility energy usage and IT equipment usage. But, once you know your PUE, it’s likely you’ll want to improve it. Measuring PUE doesn’t have to be hard.

Prevent heat and energy issues

Monitor hot spots and circuits approaching their utilization thresholds. If your facility isn't changing too rapidly, you can focus on "likely suspects"—heavily loaded circuits or difficult cabinets at the ends of rows. Targeted monitoring can have a high ROI.

Improve energy efficiency

Monitoring can allow for raising ambient air temperature and optimization of cooling efforts. Reference the following to learn more:

Six ways to lower costs through smarter cooling

Optimize your data center cooling safely, easily and cost effectively

Allocate costs and carbon emissions

Monitor at the circuit level or device level where usage is subdivided. You can allocate shared server usage and take your PUE into account when doing so. Modern technology makes monitoring at the device level more feasible than ever. If your gear is virtualized you can easily track and allocate usage to specific accounts.

How often do you need to gather data? Given the range of monitoring options available today, there is no reason to implement any type of monitoring that does not provide automated real-time collection and analysis of data. Thankfully, the days of taking meter readings by hand are rapidly fading.

Knowing in advance how you will use energy usage information will help minimize your monitoring costs. Get the ball rolling by picking a focus area, starting small and growing from there.

Monitoring can help when things go wrong

Power and environmental monitoring can reduce outages and downtime by keeping you abreast of operating conditions within your critical facilities at all times. You cannot entirely prevent outages, but you can be prepared by constantly monitoring critical equipment and overall facility conditions.

Reduce downtime

Critical facilities like data centers require a power infrastructure that is energy-efficient and cost-efficient but, above all, reliable. Downtime is expensive and even possibly "career limiting." Power problems can also result in damage to equipment. Power monitoring helps avoid downtime by providing facility management with the information needed to allocate power most effectively, detect problems early, and resolve issues with minimal disruption.

Most important: Ensuring adequate power availability. The ultimate goal is to ensure enough power is available to consistently and reliably maintain optimal equipment performance. In data centers, for instance, power requirements may fluctuate constantly. Power monitoring captures usage across time. It gives facility managers insight on what drives peak loads, real-time power system health, and longer term trends for load balancing and capacity planning. Read How Power Monitoring Helps Reduce Downtime for more information.

Managing outages from disasters

Power and environmental monitoring make it easier to maintain business continuity during a disaster event, and they give you valuable insight to improve your recovery planning. With remote monitoring systems, you can see every detail in real-time, identify and assess problems, and respond faster, all without having to be onsite. Any outage presents the same challenge—minimizing downtime and the damage it can cause to equipment, business operations, customer service, and your reputation. Whatever the disaster, your backup power source should automatically take over. Monitor these systems to ensure the failover plans are executing properly during and after an outage. Learn more at Avoiding Disaster With Smart Power and Temperature Monitoring Systems.

Remote monitoring essential for business operations

It has never been more important for your critical infrastructure to be up and running. Remote monitoring helps ensure your facilities are operating as they should be, even when no one is physically around. A robust remote monitoring system must possess several essential characteristics.

True remote monitoring

- Real-time data collection on site

- Remote data transmission from the site

- Ability to re-route monitoring data to different systems as needed

- Ability to monitor and fix the monitoring system itself. A true critical monitoring system must be capable of seamless, remote upgrades of all software and firmware components.

Flexibility

- A monitoring infrastructure must be capable of adapting with minimal human intervention

- A good monitoring system should provide the option to monitor a wide range of things.

- Easily scale from just a few sensors to thousands of sensors depending on the needs of the site.

Independence

A reliable monitoring system must be independent of the infrastructure it monitors.

- Failure of the monitoring system should never jeopardize the infrastructure it monitors. For power monitoring this means physical design making it nearly impossible for monitoring components to interrupt the flow of energy.

- Provide the option to operate and a network that is isolated from the mission-critical control networks to ensure that adding a large number of sensors doesn't create security risks in the core network.

Remote monitoring helps ensure your facilities are operating as they should be, even when no one is physically around. The benefits are clear. The next decision is which type of monitor to use—wired or wireless. Here are some things to consider about wired and wireless monitors.

Wired monitors

Simply put, wired monitors are connected to the data network via physical wires and each meter is assigned a separate network address.

Advantages of wired monitors

- Low monitor costs: Wired devices tend to be less expensive

- Speed: Wired connections can be faster than wireless although advances in wireless protocols have closed this gap.

- Reliability: A hardwired network is not susceptible to wireless "radio" interference.

- Security: There is no opportunity for someone using an unauthorized wireless device to snoop for data.

Disadvantages of wired monitors

Disadvantages of wired monitors

- Higher total cost of ownership: Installation and ongoing maintenance costs are higher than for wireless monitors. The cost to install physical wires and the IT resources needed to perform network drops, assign IP addresses, and network switches can be quite high. More time will likely be needed to access cables when performing maintenance.

- Flexibility: Physical wires reduce flexibility during installation, like when the cost to run wires to desired equipment is prohibitive. And there is a lack of flexibility when changes need to be made. Moving cables is time consuming and expensive.

- Scalability: Each additional monitor requires additional wiring work. As your needs grow you can also run into physical limitations like port availability and space for additional cables.

- Reliability: Damage to cables or cables becoming unplugged during maintenance work or human error can cause reliability problems. Some wired networks are "daisy-chained" and a failure at one point in the network will cause all downstream points to lose connectivity.

Wireless monitors

Wireless monitors do not require physical wires to transmit data. To weigh the pros and cons of a wireless monitor, you need to look at not only the capabilities of the monitoring device itself, but the wireless protocol it uses. Broadly speaking, there are some distinct advantages to going with wireless power monitors, regardless of what data transfer protocol they rely on.

Advantages of wireless monitors

- Easy to install: Wireless monitors save installation time, money, and headaches. With wireless, you don’t need to run cables through rooms, walls, or over long distances.

- Less expensive overall: Wireless monitors may cost more to purchase, but during installation and over time, the simplicity of a wireless monitor's installation and maintenance can lead to lower total cost of ownership.

- Flexibility: Wireless monitors can be installed without regard to data cabling constraints and can be located at the optimal monitoring point.

- Scalability: Leading wireless network protocols are auto-configuring, greatly reducing the time and complexity associated with planning and operating large monitoring networks.

- Reliability: Modern wireless networks are designed to automatically find a working path if a component fails.

- Security: Wireless monitoring networks can operate entirely "out of band" of core wired data networks, reducing the chance of a core network intrusion coming through the monitoring network.

Disadvantages of wireless monitors

- Signal interference: Wireless signals can lose strength over distances and between barriers (rooms, walls, equipment, etc.). And some type of devices generate radio "noise" that can create interference. Some wireless monitoring devices can also create signal interference themselves.

- Transmission rates: Depending on the protocol used, some wired connections will offer higher throughput than some wireless networks.

- Battery life: Wireless environmental monitors are often battery-powered to avoid connecting to a power source. At some point (often after 4+ years), those batteries will need to be replaced.

Packet Power delivers the security and reliability of wired monitors with the ease and cost effectiveness of wireless monitors

Custom-developed wireless protocol

We understand that standard wireless protocols such as WiFi and ZigBee often fail to provide acceptable performance and stability. So we built our own wireless protocol specifically for critical facilities like data centers.

Resilient and secure

To enhance security, the advanced mesh protocol can only carry data related to monitoring, distinguishing it from general purpose protocols. It also provides for a complete separation of the wireless monitoring network from the wired data network. The resulting mesh network is more resilient and secure than other systems.Learn more about the physics of provably safe and secure monitoring systems.

No expensive configuration required

Packet Power's self-configuring, self-optimizing mesh network makes installation and ongoing maintenance simple. Adding new monitors is easy as the system automatically configures and manages itself. Because the system determines the optimal path for every transmission, performance stays consistent even as the network grows. And every Packet Power device comes preconfigured, eliminating the need for valuable IT resources during installation.

Wireless that works

Packet Power's advanced technology delivers wireless that is proven to work in critical facilities run by colos, financial services firms, government agencies, educational institutions and telcos worldwide. In these demanding environments, the ability to handle metal and/or noise interference is critical. Packet Power's mesh topology piggybacks to form a wireless daisy chain that sidesteps interference by utilizing both 900 MHz and 2.4 GHz technology. Packet Power wireless monitors have never failed to make a strong network connection in any facility where they've been installed.

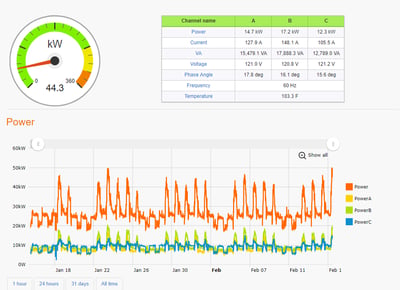

Power usage in a data center fluctuates constantly. Managing it well extends the useful life of the facility. Monitoring information can help allocate operating costs, ensure power is used effectively, minimize cooling costs, avoid hot spots and outages, and track compliance with regulations and service level agreements.

Power monitoring benefits

Monitors capture usage across time and give facility managers insight into what drives peak loads, real-time system health, and longer term trends for load balancing and capacity planning.

Efficient power distribution

Facility managers can see where the load is coming from and move it to the UPS, PDU, or RPP where capacity is most available. At the cabinet level, monitoring helps ensure the load is balanced by phase in cabinets with three-phase power sources. It's not uncommon for there to be a gap between the known load from the utility meters and the load being measured. A well-metered facility makes it possible to identify 100% of the load.

Scheduled downtime

Power monitoring allows you to track the load on primary and secondary power sources so you can be confident there will be enough backup power available to cover planned downtime.

Adequate cooling

Heat hurts computing performance, damages equipment, and can cause outages. Power monitoring shows you how much power you’re using both for computing and cooling – essential data for calculating PUE.

Branch circuit monitoring

Power monitoring at the branch circuit level (the level that feeds power to cabinets) gives you a very detailed picture of power usage. You can allocate expenses more precisely, unburden overloaded circuits, and better spot available power. This information lets you redistribute power as needed to maintain optimal balance.

Phase-balancing

Today it's typical for branch circuits to use three-phase power. If the phases are not equally loaded, power is used less efficiently. And if load by phase is really neglected, it could lead to a plug bank breaker tripping on the rack PDU. Power monitoring shows consumption by phase (often displayed right at the cabinet), highlighting any load imbalances.

Insight

Beyond streamlining day-to-day operations, power monitoring can help:

- Detect problem areas early

- Avoid unnecessary infrastructure upgrades

- Lower the risk of unplanned outages

- Budget for future demand effectively

Additional power monitoring information

Metered, monitored, switched, smart: Comparing types of PDUs

Power distribution units (PDUs), commonly referred to as power strips or rack mounted distribution units (RMPDUs), are critical components within a data center’s power hierarchy. PDUs range from basic PDUs to various types of smart PDUs. This article clarifies PDU options and how they compare.

The best way to access a voltage source

Accessing the voltage source when installing power monitors can be done using a variety of methods. This is a quick summary of the most common ways to tap into a voltage source.

Current Transducers: Split core, solid core and why you should care

The current transducer is at the heart of every power monitoring device. Here is a quick review of AC power CTs.

Split core CTs and why size matters

Split core CTs come in a variety of formats, sizes, current ratings and accuracy levels. The inside diameter of a CT is important for a number of reasons.

Using Rogowski Coils

Conventional split core CTs may not always be the best solution when installing current transducers. An easy alternative is to use a Rogowski coil.

Shower or bath? IP44 vs IP67

Power connectors are selected based on maximum amperage and voltage as well as how well they can protect from external solids and liquids. Read on if you’ve ever wondered why IP67 connectors can cost 10 times more than IP44 connectors.

Packet Power power monitoring solutions

Monitoring Made to Measure

Your power monitoring needs are unique. And you need a system built specifically to meet these needs. With Packet Power’s “Monitoring Made to Measure” approach to building power monitors, you get a system that is built to your facility’s exact specifications. Custom built monitoring devices are easy to install and require no special configuration. They begin transmitting real-time data wirelessly and securely as soon as they’re installed and powered up.

Full power vs. current-only

Packet Power offers the flexibility to monitor full power, current-only or a combination of both. Current-only monitors are generally less expensive and should be considered when you mainly want to know the state of a device, for example if a generator is on or off. Full power monitors are the right solution when it is important to track energy at the highest level of accuracy on every circuit or if you need to understand power factor at the branch circuit level. A combination of full power and current-only is also possible. Learn more about current-only vs. full power monitoring options.

Branch circuit monitors

Packet Power Branch Circuit Monitors offer the ideal way to add monitoring to any panel whether it’s a single power distribution panel or a four-panel RPP or PDU. Designed to minimize installation time, the custom-built system fits in even the tightest spaces, comes fully configured, and avoids the need to run data communications wiring. The Branch Circuit Monitoring installation video demonstrates the ease of installation.

Multi-circuit monitors

Easily add power monitoring to existing equipment just where you need it and configured exactly as required. Packet Power multi-circuit monitors support 6 to 72 current senators giving you the flexibility you need to monitor critical equipment. The custom-built devices are as easy to install as our Branch Circuit monitors.

Single meters

Packet Power offers a range of full power or current-only meters that support 1 to 8 current sensors and are line-powered on circuits up to 600V. Systems can be shipped fully configured and ready to install to greatly reduce installation time and cost.

Full power vs. current-only

Packet Power offers the flexibility to monitor full power, current-only or a combination of both. Current-only monitors are generally less expensive and should be considered when you mainly want to know the state of a device, for example if a generator is on or off. Full power monitors are the right solution when it is important to track energy at the highest level of accuracy on every circuit or if you need to understand power factor at the branch circuit level. A combination of full power and current-only is also possible. Learn more about current-only vs. full power monitoring options.

Smart Power Cables

Smart Power Cables are power cables with embedded wireless power monitors. They are the easiest way to add metering to any device that has a plug. Smart Power Cables are ideal for monitoring non-power strip devices such as SANs, mainframes and switches. They also offer the simplest and most-effective way to convert any unmetered rack PDU into a smart PDU.

Installing a Smart Power Cable is truly plug-and-play. This video demonstrates just how fast and easy installation is.

DC power monitors

Packet Power wireless DC power monitors capture power usage on DC power circuits. The compact monitors capture energy usage on circuits ranging from 20 to 3000 amps on 5-24V, 48V and 200-380V DC systems. They can be installed at the panel, BDFB, or cabinet. Installing at the cabinet level means you can avoid the densely-packed panels. Wireless options mean there is no need to add additional data communications wiring.

Smart buildings prevent problems. Getting real-time data on temperature, humidity, and differential pressure in a data center can help optimize operations, extend equipment life, lower energy use, reduce cooling costs, and prevent disruptions.

Remote environmental monitoring systems make your building smarter and keep you out of crisis. These devices can help:

- Identify and track hotspots

- Focus cooling where it’s most needed

- Identify wasted or misdirected airflow

- Provide the information to safely raise ambient temperatures

- Monitor compliance with industry standards and service level agreements

- Verify the effects of containment systems

- Validate cooling optimization efforts

Reducing cooling costs

Cooling costs represent one of the largest expenses of operating any data center. But figuring out how to get the information needed to drive costs down can be confusing. Here are several ways to break the overall challenge into manageable projects as well as what you need from a monitoring system to support each approach.

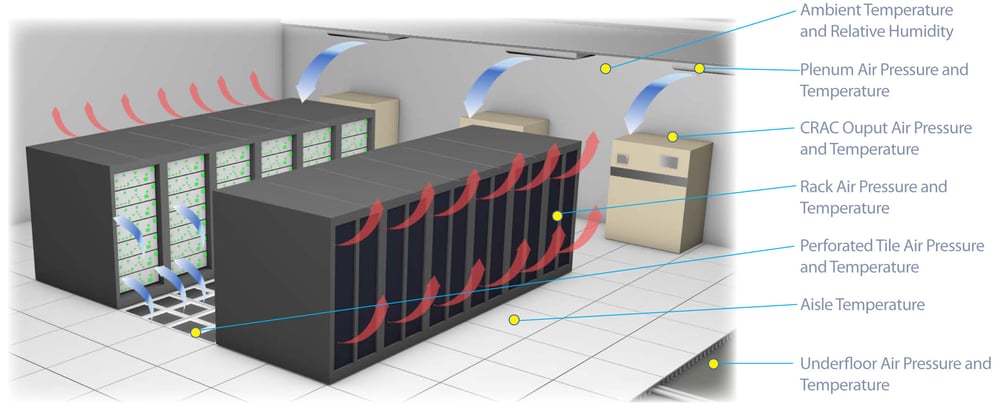

Cooling system performance

Changes in the performance of a cooling system may not be easily identified as they may happen gradually or be very location specific. Placing environmental monitors in strategic locations will identify changes in cooling system performance caused by equipment deterioration or failure as well as physical obstructions or changes to the data center layout.

Monitoring features to look for:

- Flexible monitor placement—floor, ceiling, by a door, beside your computer room air handler (CRAH)

- Monitor portability—move monitors to wherever you suspect problems

- Easily scalable

- Custom alerts based on your tolerance factors

Data center cooling optimization

Many data centers operate at far cooler temperatures than required by customers or industry standards. This is done to account for any possible condition that may be occurring in any rack at any time. This "abundance of caution" comes at a high energy cost and it creates an opportunity for substantial cost savings for many data centers.

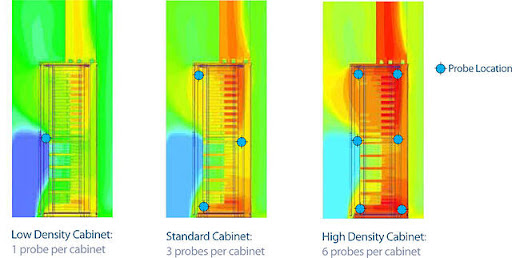

Rack inflow temperature monitoring can provide a baseline for cooling performance. Remember that a rack does not have a single temperature and not all racks are the same. A high density rack can have large temperature variations within the rack. And power density can vary widely from rack to rack.

Monitoring features to look for:

- Flexible monitor placement—within and between racks, end of aisles, wherever you are considering adjustments

- Multi-point monitoring within a single rack

- Easily scalable

- Real-time reporting to monitor effects of changes made

- Custom notifications and alerts based on your performance targets

Learn how Data center cooling optimization is easier than you think.

CRAC / CRAH efficiency

Environmental monitoring encompasses tracking differential pressure and humidity as well as temperature. Adding differential pressure and humidity sensors in strategic areas on the computer room air conditioning (CRAC) or computer room air handler (CRAH) and plenums provides detailed performance and can help identify optimal settings.

Monitoring features to look for:

- Differential pressure and temperature sensors available

- Flexible monitor placement

- Custom reporting to ensure efficient equipment operation

Service Level Agreement (SLA) Compliance

Colocation providers often have agreements with customers to maintain specific environmental conditions. This typically consists of rack level temperature monitoring with the corresponding documentation to show compliance.

Monitoring features to look for:

- Multi-point monitoring within a rack and between racks

- Easily scalable

- Immediate logging and alerts

- Segregated customer reporting

Facility performance benchmarking

Cooling systems can be influenced by changes in the data center and equipment performance. These can be subtle changes that are hard to track. A basic environmental monitoring system provides all the data needed to benchmark temperature, airflow distribution and energy usage over time.

Monitoring features to look for:

- Low cost, quick and easy installation

- Flexible monitor placement

- Custom reporting that tracks conditions over time spanning days, weeks and months

As changes are made to contain and control airflow and gradually raise temperatures, environmental monitors can track performance at the desired level of detail. Raising cooling temperature by as little as one degree can have a 3-5% impact on energy costs.

Temperature

Temperature changes can be the difference between well-running and overheated equipment as well as cooling costs within budget and uncomfortable budget review meetings with Finance. Keeping the data center at the right temperature helps your facility run smoothly.

ASHRAE give this guidance for air temperatures at rake intakes:

- Recommend range of 18° - 27°C (65° - 81°F)

- Allowable range 15° - 32°C (59° - 90°F)

Finding hot spots in your data center

Hot spots in a data center must be closely monitored: let the warmest areas in your facility get too warm and you risk degraded performance, outages, and potential equipment damage. Yet they can also drive how much you spend to cool your entire data center. The key is to find them, monitor them, and manage them.

How to pinpoint hot spots in your data center explains how to locate hot spots, short and long term actions you can take to manage hot spots to avoid future problems.

Humidity

Water is the enemy of electronics, but so is air that is too dry because static electricity can build up and pose a risk. The goal is to keep relative humidity in a data center within a safe range. That requires knowing the dewpoint limits as well.

ASHRAE recommends data centers and server rooms have:

- Lower dew point limit of 5.5°C or 41.9°F

- Upper dew point limit of 15°C or 59°F

- Maximum relative humidity level of 60%

With multiple dew-point monitors, you can detect potential air mass mixing or (de)humidification, indicating opportunities for potential energy optimization.

Differential pressure

While cool air is one of the most valuable commodities in a data center, optimizing air flow and cooling can be difficult without a good picture of air movement through your data center. By using differential pressure sensors, it becomes easy to get a clear understanding of the air flow patterns throughout your data center. The cost and ease of implementation can translate to an ROI in as little as one month.

Understanding differential pressure zones and airflow allows you to:

- Identify wasted or misdirected air pressurization / flow

- Make the changes to optimize flow utilization

- Focus cooling resources and air flow on areas where it is most needed

- Easily verify the effects of cooling and air handling efficiency efforts

- Be alerted to any changes that may occur in pressurization indicating potential leaks or changes in air handling performance

- Correlate air pressure / flow changes with temperature changes (using available temperature probes)

Optimizing data center cooling using differential pressure sensing explains in more detail what differential pressure tells you and provides a number of pressure monitor installation examples.

Packet Power environmental monitoring solutions

Wireless monitors

Battery or AC power? One reading per row or 12 readings per rack? No problem. Packet power’s range of wireless environmental monitors combines industry-leading flexibility with exceptionally low costs. Track temperature, relative humidity and differential pressure where needed.

Accessories

Packet Power offers temperature probes in a variety of lengths as well as pre-assembled temperature probe kits for common rack configurations. A leak detector probe that senses the presence of water is also available.

Installation to information in minutes

Simply add the monitors exactly where you need them. The monitors automatically join the wireless mesh network providing real time monitoring data immediately upon powering up. Access the data from your DCIM or BMS via common protocols. If you don’t already have a monitoring software solution, leverage Packet Power’s EMX monitoring software.

See just how easy it is to install Packet Power environmental monitors in this video

In this case study, a global colocation services provider installed Packet Power environmental monitors in one-tenth of the time as their old system and their reporting reliability improved by 20%.

Once monitors are installed in a data center, you need to determine how to best analyze and act on the data being collected. There can be hundreds or thousands of readings each hour so manual collection and review is not an effective option.

There are a variety of software solutions that can gather, organize, generate reports, issue alerts based on user parameters. Good monitoring software solutions provide 3D visualizations, dashboards, and interactive reports. More sophisticated solutions not only enable monitoring but also deliver the capability to take action remotely—change AC temperature and sound alarms.

Software options

Data Center Infrastructure Management (DCIM) software

Data center infrastructure management (DCIM) tools monitor, measure, manage and/or control data center resources and energy consumption of both IT-related equipment (such as servers, storage and network switches) and facility infrastructure components (such as power distribution units and computer room air conditioners).

They are designed for data center use, rather than general building management system (BMS) tools, and are used to optimize data center power, cooling and physical space. DCIM software can bridge information across organizational departments—Data Center operations, Facilities, and IT.

Building Management System (BMS) software

A building management system (BMS), otherwise known as a building automation system (BAS), is a computer-based control system installed in buildings that controls and monitors the building's mechanical and electrical equipment such as ventilation, lighting, power systems, fire systems, and security systems.

A building management system (BMS), otherwise known as a building automation system (BAS), is a computer-based control system installed in buildings that controls and monitors the building's mechanical and electrical equipment such as ventilation, lighting, power systems, fire systems, and security systems.

Other

BMS and DCIM systems are significant investments in time (multi-year procurement and deployment) and resources (people and money). They are generally only cost-effective for very large organizations. One of the ongoing problems facing these large deployments is the difficulty in accurately measuring the return on investment from these applications.

Smaller organizations or those unwilling to take on a large multi-year deployment and expense have other options. These monitoring software solutions likely have fewer features than full DCIM or BMS solutions. They also generally don’t include management capabilities like automatically changing the AC temperature setting based on set criteria or sounding a physical alarm when load exceeds a certain capacity. The trade-off for fewer features and functionality is quicker time to deployment, lower cost and faster time to value.

Packet Power monitoring software

Many BMS and DCIM applications have to be extensively customized before they can provide useful information. Often this requires the use of expensive consultants and adds months (or even years) to a monitoring deployment. Packet Power’s EMX Energy Portal is an alternative monitoring software solution to BMS and DCIM systems.

EMX is the easiest, fastest path to energy and environmental insights. It provides instant access to full power and environmental monitoring data at a fraction of the cost and complexity of competing solutions and without the need for external consultants.

EMX features

- Real-time and historical power, temperature, humidity and pressure information

- Accessible from any web browser

- Supports a multi-tenant model making it a strong fit for colo companies

- Common reports are built in with a wide range of report customization options

- Easily create custom graphical dashboard views and share securely

- Highly flexible alert capabilities at the device, cabinet and room levels

- Offered as a cloud-based service or local software application

Reference What you need to know to manage your data center more effectively for more information.

Data centers must meet constantly evolving needs. Trends such as increasing power density, cloud computing, edge computing, and data analytics ultimately place differing demands on the data center. This often requires that improvements be made to existing facilities to enable the facility to meet the new demands. This process often is referred to as “retrofitting”.

Retrofitting possibilities are as broad as the data center’s evolving needs, but generally, they provide a cost-effective option for increasing efficiency or capacity without disrupting your building infrastructure or operations. A retrofit can address an acute problem or be part of an ongoing enhancement strategy. It can be as simple as adding wireless monitoring or as complex as changing out mechanical, electrical, and plumbing (MEP) utilities.

Retrofitting starts, progresses, and ends with data collection

Regardless of the retrofit objectives, you need data to determine where to focus your efforts, whether or not those efforts are achieving desired goals, and how to refine your efforts to continuously improve results. Identify the type of data to collect based on your overall retrofit objectives.

Improve infrastructure efficiency

Even if this isn't the primary retrofit goal, there are always opportunities to increase efficiency and decrease operating costs.

- Track power usage of high energy use equipment like heating and cooling systems, generators, UPSs and transfer switches and determine if new equipment is necessary.

- Track temperature and humidity at the cabinet, aisle and room level to find opportunities for cooling optimization that doesn’t rely on turning up the AC or investing in expensive new equipment that may not be necessary.

- If new equipment is necessary, track expenses after the new equipment is installed to report cost savings.

- Review cabinet and circuit level power use

Optimize or increase capacity

There may be opportunities to optimize existing equipment before needing to invest in new equipment.

- Track power use at the cabinet level

- Look for abandoned power

- Seek opportunities to balance loads

- If new equipment is installed, benchmark energy use of old equipment and compare against new equipment energy use to determine cost savings.

Improve operational efficiency

New equipment can reduce operating expenses, but automated processes can save time and make better use of your team’s time.

- Automating data collection ensures consistency and frees valuable resources to focus on reviewing the data. You can have data without information, but you cannot have information without data.

- Leverage remote alert systems so people aren’t required to be onsite to hear local alarms; customize the criteria for triggering an alert and choose who gets notified.

- Make the data easily accessible to the right decision makers

Add monitoring to automate data collection

How to grow into data center monitoring without breaking your budget or your career provides eight best practices for getting started with monitoring.

In the face of change, maintain monitoring fundamentals

Keeping up with changing data center demands does not mean constantly replacing your critical infrastructure with new components. But getting the most out of your existing infrastructure does require a clear understanding of the demands being placed on it, and in a data center, that kind of awareness is only possible through monitoring. This awareness will help plan, accomplish and verify any retrofitting needs you may have, regardless of the scope or complexity.

Making the case for monitoring

You know that your team can use energy usage data to help ensure your entire facility runs more smoothly. Monitoring can also save money by reducing costs and extending the life of critical equipment. It can identify inefficient energy use and times when buildings are approaching peak demand usage triggering peak utility pricing.

Monitoring can highlight ways to safely reduce cooling costs. Monitoring delivers the data to help in capacity planning. It can help identify when additional capital expenditures will be needed or that such investments can be delayed.

Even though we know the benefits of monitoring, it can still be viewed as "non critical" when budgets are constrained. Here are a few tips to help make the case for adding power and environmental monitoring to your critical facility.

Start with the current challenges your team is facing. What questions keep coming up? What challenges are you trying to address?

- Which circuits could handle more power?

- Is there equipment at risk of exceeding its capacity?

- How do you cut cooling costs without jeopardizing expensive equipment like servers, switchgear, HVAC units, and generators?

- Which tenants are using the most energy?

- Do you have the information needed to allocate energy costs based on usage?

- Why are utility costs so much higher than budgeted? Where can you save money?

- Can demand be shifted to avoid peak load pricing?

- Is there a simple way to know when cooling or heating equipment is running, or not running?

- Did the generator turn on when the power went off?

- Are the lights being turned off when they should be?

- Is water present where it shouldn't be?

Power and environmental monitoring can be a simple and low risk investment that quickly answers these questions and provides tangible benefits.

Productive facilities managers are successful by adding monitoring in stages that are low cost, quick to deploy, and quick to start generating useful data that pays for itself. This approach is also generally easier to get budget approval. Starting small and showing tangible results helps make the case for the next stage of investment—in capital expenditures or additional monitoring.

Monitoring can also lead to increased organizational effectiveness. Introducing a monitoring solution to replace routine tasks can free up employees to work on more important tasks or critical projects. This shift in human capital can result in greater organizational efficiencies, increased staff productivity, and reduced risk.

Share the insights you've learned from monitoring. You'll build valuable relationships internally and externally using data-driven information that helps address real business challenges. You'll also be in a better position to submit future funding requests when they're backed by prior business results.

Thanks to advancements in wireless technology and the miniaturization of devices, it’s not as hard (or costly) as you may think to retrofit a data center with power and environmental monitors.

Additional data center retrofitting information

Power monitoring ROI

There are countless reasons to monitor power in data centers. We’ve outlined some of the most common applications and the resulting benefits. Often the determining factor in deciding to install power monitoring is the initial capital expenditure. Lower cost monitoring solutions coupled with measurable returns help justify the investment.

One path to “Monitoring Nirvana”

A synopsis of an article in the Data Center Journal written by Leon Adata entitled “Monitoring Nirvana” describing data center monitoring and who should be doing it.

Monitoring insights deliver energy savings

The Center for Energy and Environment (CEE) finds “solid opportunities to improve energy efficiency” for smaller facilities including data closets.

Rescuing stranded smart devices in your facility

You’ve invested in smart monitoring devices. They’re in the desired location, next to the equipment you want to monitor. But your facility’s layout can make it difficult to connect these metered devices to your network. Running data communications wire may not be possible due to physical limitations or the cost of running wire is too prohibitive. The result is a stranded monitor. Packet Power’s Wireless Network Connector is a cost-effective solution.

Power is an essential part of data center operations. Data center managers must ensure enough power is always available. This has always been a challenge. But the challenge has grown as data center managers must also contend with delivering far more power per square foot of data center space—and delivering it more efficiently.

We believe it’s important to know your power. So we’ve included some information to ensure you’re a well-informed consumer of electrical power.

Understand power: Volts, Amps, Watts, Watt-hours and Cost

We live in a world of electrical power. It runs our lights, heating, cooling, computers and machinery. Read for a quick review on the basics of electricity—Volts, Amps, Watts and Watt-hours and well as an overview of costs.

Three-phase power or the magic of the missing neutral

Few things seem to cause as much confusion as three-phase power, especially in a Delta configuration. Three-phase power is explained using a plumbing analogy.

Power Factor: The difference between promise and reality

You may be getting less power throughout your facility than you think, thanks to something known as power factor. Power factor affects power management, especially if you’re running very high power equipment such as an uninterruptible power supply (UPS). Power factor also affects accurate cost measurement since you are effectively getting less usable power than you’re paying for. It pays to understand power factor and how it affects your operations.

Total harmonic distortion: What happened to my perfect wave?

Total Harmonic Distortion (THD) is, at its most basic, a measure of how much your load is distorting the perfect waveform of the power provided by your utility. THD is always present in current and voltage but too much distortion can cause problems.

Baby you can drive my (electric) car!

An electric car is basically multiple computers with a bunch of batteries and an electric motor or two on four wheels. Just like your average computer, it consumes electrical energy. Have you ever wondered how far your average rack of servers could take you if it was an electric car?

FREE DOWNLOAD

Would you like a copy of the Guide to Data Center Monitoring to read later?

Complete the form to download a PDF

Take me to the form

About Packet Power

Packet Power develops and manufactures wireless power and environmental monitors and associated cloud-based data services to make buildings smarter.

By focusing on products that are easy to install and manage, Packet Power makes it easier and less expensive for critical facilities managers to get the information needed to lower costs, avoid outages and improve operational effectiveness.

Contact Us

Don’t have time to read the whole guide?

Don’t have time to read the whole guide?